Printing plate archiving with „coe cam“

Still waste a lot of time trying to find the right printing plate and tired of deciphering the small print on the labels? Maybe you even order plates several times because you can't find the right one again?

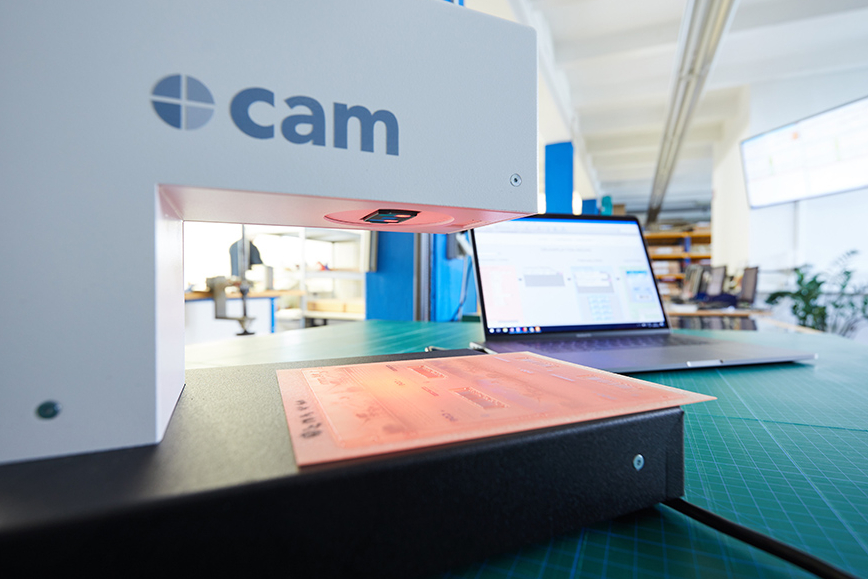

We at coe help you to bring efficiency into your archiving. For this purpose, we have developed the "coe cam" - a camera-based flexo plate recognition system.

With the „coe cam“ you can archive your printing plates:

- Safe

- Efficient

- Automated

- Convenient

The system also supports you in retrieving your flexo plates. Archiving becomes smarter and clearer with the „coe cam“. Save time and money!

Alle Vorteile der „coe cam“ im Überblick

SECURE ARCHIVING OF THE PLATE

CLEAR RECOGNITION OF THE PLATE

PLATE CHECK BEFORE PRINTING

CORRECT TOOL IN THE PRESS

LOG OF PLATE PERFORMANCE

ENTIRE PROCESS BECOMES SAFER

ENTIRE PROCESS BECOMES MORE TIME-SAVING

INCREASED COMPETITIVENESS

How does the archiving of printing plates work?

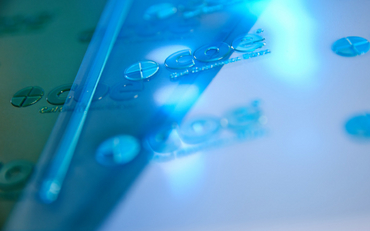

The basic prerequisite for automated plate archiving is a unique plate identification system that is independent of plate type or colour. You can retrieve the respective plate easily and quickly in a database. A special camera reads an integrated 2D code on the plate that contains the plate's identification number.

![[Translate to Englisch:] Druckplatten-Archivierung mit COE](/fileadmin/images/archivierung/druckplattenarchivierung_test.jpg)

![[Translate to Englisch:] Archivierung Ihrer Druckplatten - Carl Ostermann Erben](/fileadmin/images/archivierung/druckplattenarchivierung_coe.jpg)

Areas of application for automatic plate recognition

The areas of application offered by such a system are manifold: clear recognition and control of language variants, logging of the plate’s running performance, allocation of 3rd party supplied plates or plate changes. We would be happy to discuss your specific application.

Tips for storing and handling printing plates

Ideally, store printing plates in a closed, light-proof bag. Our experience has shown that a constant temperature of approx. 21 °C and 60 % relative humidity contribute to a longer life of printing plates. Treatment of the plate also plays an essential role. Therefore, avoid allowing plates to remain dirty and clean them immediately after printing. As a rule, we assume a plate life capacity of approximately 100,000 running metres. This rule of thumb can deviate upwards or downwards depending on how well the plate is looked after.

We are also happy to support you

in all other areas of prepress –

we are your …

… flexographic printing

plate manufacturer

We produce flexo plates with the very latest digital imaging technologies on state-of-the-art processing equipment. This guarantees high-end results, tailored to your specific application conditions.

Read more

… Printing plate manufacturer

for letterpress printing

For the multitude of letterpress units in label printing, we produce foil- and steel-based letterpress plates. We also have the right plate for coating or varnishing

Read more

… rotary screen manufacturer for print finishing

We are experts in the entire process of producing rotary screens; starting with different types of meshes for your finishing application, through imaging screen printing plates to manufacturing screen printing cylinders.

Read more

Reproducible printing forms

ISO certified,

consistent quality

Efficient workflows

Shortest delivery times

Use of the latest technologies